Concrete Scanning vs. X-Ray: What’s the Difference?

Concrete scanning usually happens in the quiet moment before everything gets loud. The slab looks solid, the plans look clean, and the pressure is on the next decision. Many crews expect one scanning method to handle every job, but the field has other ideas. Site access, safety rules, and schedules all shape the choice.

Ground penetrating radar (GPR) and concrete X-ray each come with tradeoffs that matter long before the first cut. If you pick the wrong approach, you can stall crews, trigger shutdowns, or end up rescanning, and the cost shows up in time, money, and trust on-site.

How Ground Penetrating Radar Scans Concrete

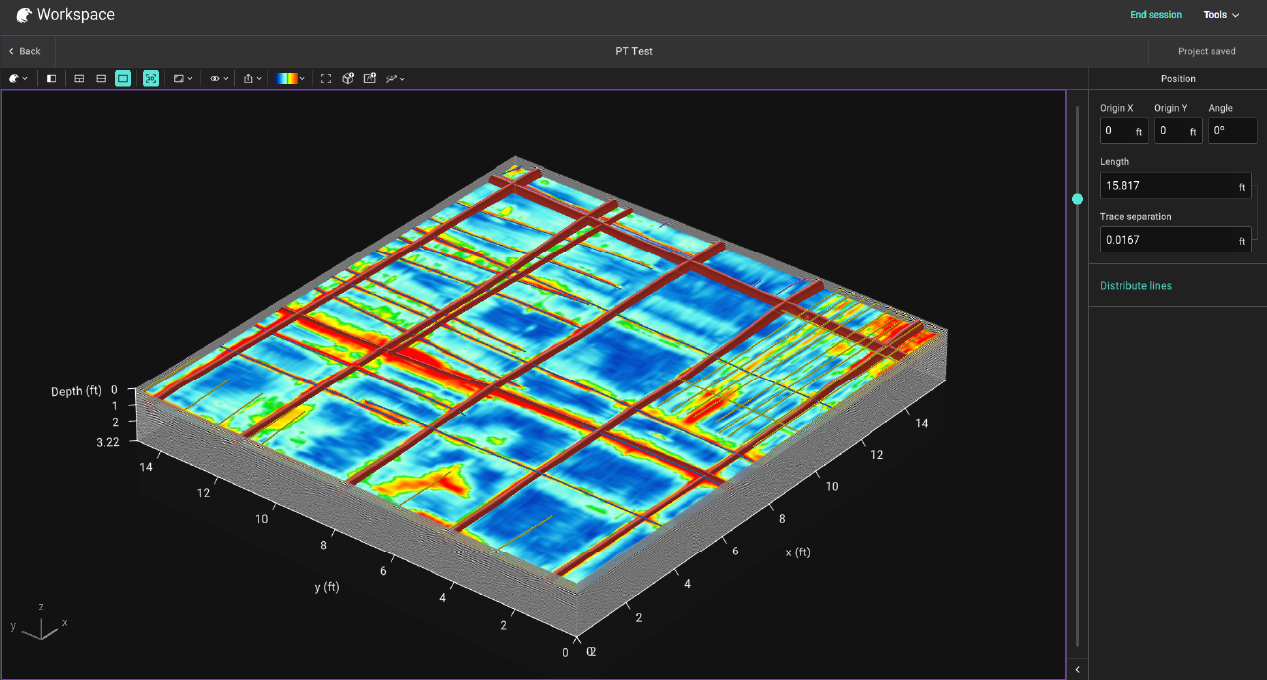

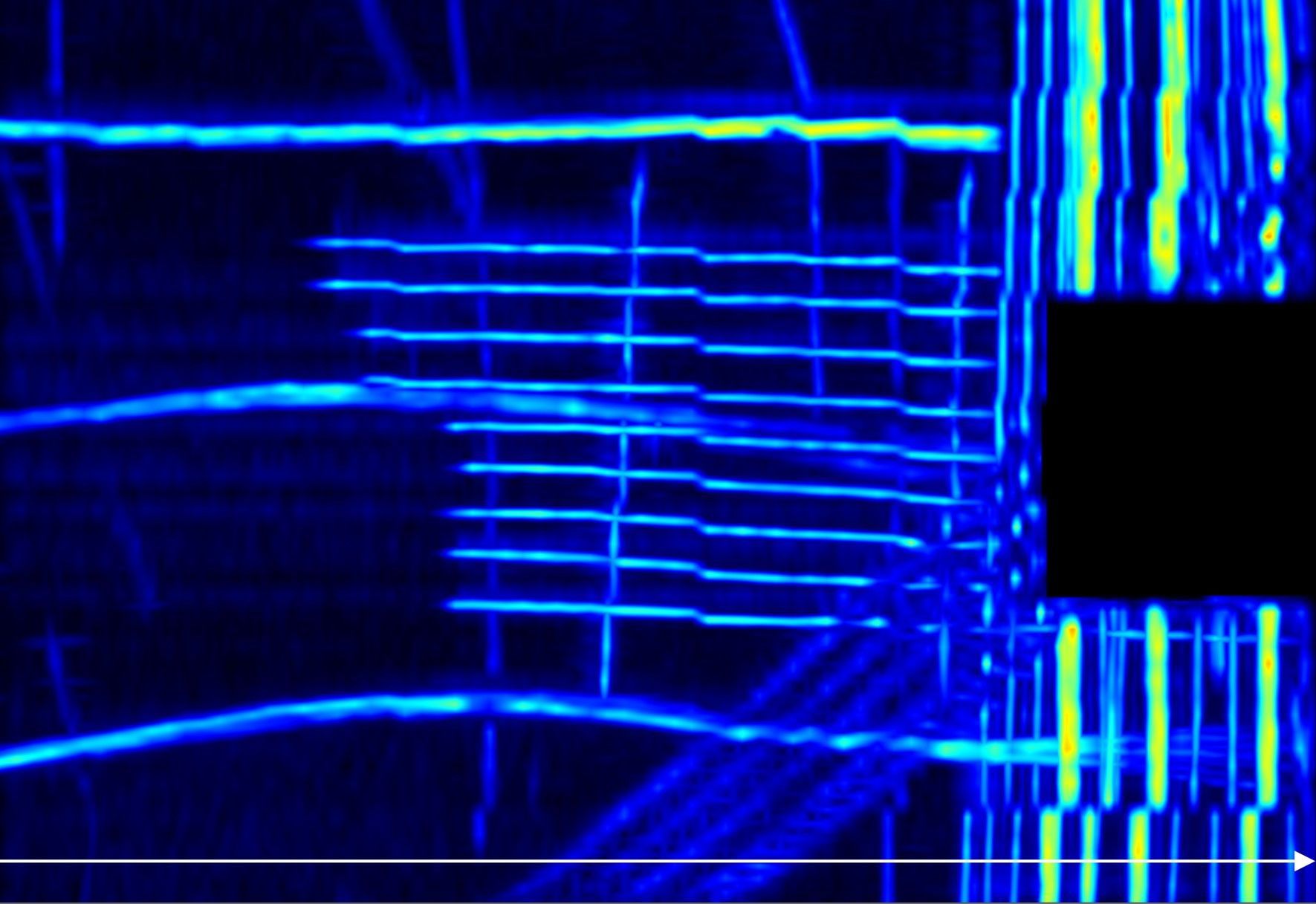

Ground penetrating radar sends electromagnetic signals into the slab and listens for what comes back. Those signals bounce off rebar, post-tension cables, conduit, or voids. The scanner tracks timing and signal strength, then turns that information into a picture that operators can read. Depth, spacing, and alignment show up in real time while they move across the surface.

This method works well on active jobsites because everything happens from one side of the slab. There is no need to reach both faces. Nearby areas can stay open instead of sitting in a restricted zone. Crews can scan, mark, and keep production moving during normal site activity.

Conditions in the field rarely stay perfect. Radar still performs when slab thickness changes, moisture levels shift, or reinforcement patterns do not match the drawings. Results sharpen when trained operators recognize signal patterns and typical construction habits. That experience lines up closely with the most common uses for GPR on concrete jobs.

For most concrete projects, radar scanning supports steady progress and cuts down on unpleasant surprises inside the slab.

What X-Ray Concrete Scanning Is Used For

X-ray scanning has been used in concrete inspection for decades. Radiation passes through the slab and hits the film or a digital plate on the far side. That exposure creates a shadow image that shows rebar, conduit, and other embedded pieces.

Concrete X-ray usually comes into play when crews can reach both sides of the slab. Open decks, precast yards, and controlled shop spaces tend to fit this method. Work often slows or stops during scanning because radiation requires exclusion zones. Crews clear the area while technicians take each shot.

Images can look sharp when layouts stay simple. Heavy reinforcement or thicker concrete can make readings harder to interpret and drag out the process. Setup time grows when several exposures are needed to cover one location.

This method still fits specific situations. On busy jobsites, limits around access, safety, and schedule often push teams toward faster scanning methods that keep surrounding work active.

Jobsite Safety Differences Between GPR and X-Ray

Safety conversations usually start before anyone draws a single mark on the slab. Crews think about how close they can work, who needs to clear out, and how much time they might lose. Radar scanning tends to fit into that flow. Crews keep working, and the site keeps moving.

Ground penetrating radar on busy jobs usually means:

- No radiation exposure for nearby trades

- No shutdown zones or evacuation calls

- Scanning was done from one side of the slab

- Easier planning on tight schedules

Concrete x ray safety planning often includes:

- Cleared exclusion zones for each scan

- Work on hold in nearby areas

- Extra oversight from safety staff

- Less flexibility on crowded floors

Those gaps show up quickly on real projects. Radar lets scanning happen inside normal jobsite patterns. X-ray methods force the site to bend around the scan, which can add pressure to timelines and coordination when multiple crews share limited space.

Accuracy and Depth Comparison for Concrete Scanning

Accuracy matters most when crews trust marks to keep bits and blades away from steel or conduit. Radar scanning holds up across a wide mix of slabs. It spots targets and gives depth estimates while the operator moves across the surface, so crews can keep working instead of stopping to sort through readings.

X-ray images can look clear in thinner slabs and simple layouts. Reading depth from those images leans on scale and the technician's experience. In thicker concrete or heavy steel, results get harder to read and often require extra shots, which adds time.

| Comparison Factor | Ground Penetrating Radar (GPR) | X-Ray Scanning |

|---|---|---|

| Typical slab thickness | Handles a wide range of thicknesses | Works best on thinner slabs |

| Depth information | Depth estimates available in real time | Depth interpreted from the image |

| Dense reinforcement | Can read through congested steel | Image quality often drops |

| Rescans required | Less common | More common |

On active projects, steady, predictable accuracy helps crews trust their marks, keep tools moving, and avoid stopping work just to double-check what sits inside the slab.

Setup Time and Site Access on Active Projects

Setup time decides how scanning fits into the day’s work. Radar carts roll onto the slab, get checked, and start marking in short order. One technician can move through tight corridors, elevated decks, or finished spaces without pushing other crews out. That kind of flexibility helps on floors shared across several trades.

On most jobs, radar setup usually looks like:

- Access from one side of the slab

- Easy movement through active areas

- Little prep before scanning starts

- Quick shifts between scan locations

X-ray scanning requires more staging. Technicians need access to both faces of the slab, place film or plates, and set up exclusion zones. Nearby work goes on hold until each exposure is done. Crowded sites feel that slowdown even more.

On active projects, a quicker setup keeps work moving. Fewer access limits make planning easier, reduce friction between crews, and help schedules stay close to what was promised.

Choosing the Right Method to Avoid Costly Hits

Every project starts with a plan that assumes certain conditions in the slab. Those assumptions get pushed hard once saws show up, and the schedule tightens. Ground penetrating radar tends to fit most active concrete work because it adjusts to changing layouts, shared floors, and shifting priorities. Crews get depth readings they can use, clear marks on the surface, and fewer stops in the middle of the day.

Concrete X-rays still show up on jobs where access stays open and time is easier to control. For slabs tied into

underground mapping work or areas already cleared of traffic, it can give helpful confirmation. On live floors, the extra rules and pauses often outweigh what it adds.

GPR cost usually comes down to speed, access, and less downtime. Fewer shutdowns and quicker scanning protect production while lowering exposure risk. Concrete X-ray often brings extra labor and schedule hits that show up later in the budget.

In the end, the right choice follows site reality, not habit.

GPR USA works alongside field teams to match methods, training, and ongoing service to the conditions they face.

Contact us to talk through your next project.