Top Uses for GPR in Construction Projects

Not every risk on a construction site is visible. Beneath the surface, concrete hides rebar, conduits, and voids that don’t show up on blueprints or appear in the wrong place. Crews rely on experience, but they also know that guessing isn’t worth the cost of a hit. That’s where

GPR construction tools change the game, bringing clarity and confidence to every scan, core, or cut.

Locate Rebar and Conduit Before You Cut or Core

When you're cutting into concrete, the last thing you want is to strike embedded rebar or electrical conduit. Striking either turns a simple task into a shutdown. Equipment gets damaged, safety takes a hit, and timelines slip fast.

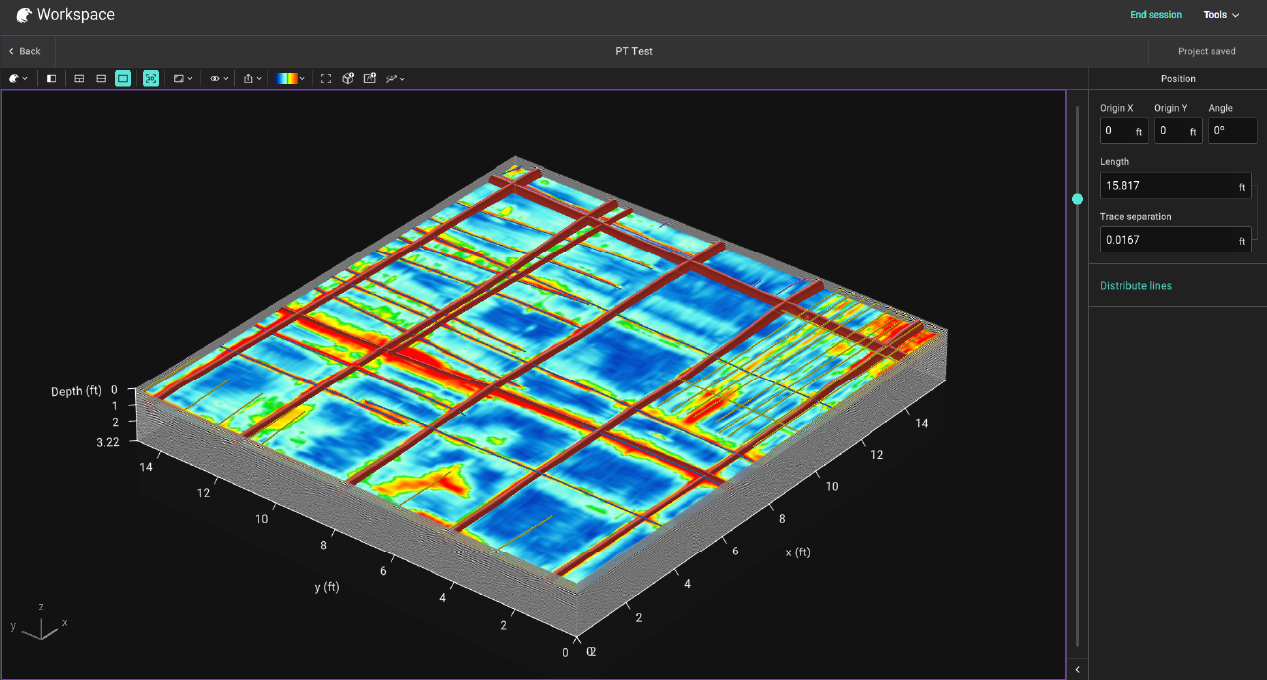

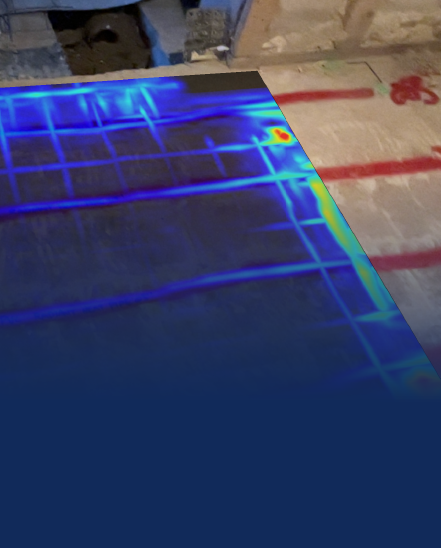

GPR construction tools help teams scan slabs and walls before the blade ever touches the surface. You get a clear view of what’s inside the concrete, so you can mark your safe zones with confidence. Unlike older methods or incomplete as-built drawings, GPR adapts to real-world conditions, even in congested areas.

Coring, trenching, or anything in between, scanning ahead keeps crews clear of surprises and the site safer. That’s why more teams are making concrete scanning part of their pre-cut checklist. The ability to pinpoint

materials that GPR can detect makes it even more valuable in unpredictable conditions.

Avoid Utility Hits When Drilling Into Concrete

Even experienced teams run into problems when buried utilities don’t match the plans. Drilling into live electrical, plumbing, or communication lines puts workers at risk and sets off a chain reaction of delays, cost overruns, and liability headaches. GPR construction scanning adds the visibility needed to avoid those hits before they happen. It maps embedded utilities in real time, even when the site has been patched, modified, or undocumented.

When you’re anchoring equipment, running fasteners, or setting dowels, knowing what’s just below the surface can make the difference between a clean install and a major problem. GPR helps crews drill with certainty, not guesswork. In places like hospitals, data centers, or high-traffic commercial sites, precision keeps the work predictable. Crews rely on it to avoid disruptions and stay on schedule without compromising safety. It’s a key part of

underground utility mapping when accuracy is non-negotiable.

Measure Concrete Thickness

Concrete thickness plays a direct role in safety, structural planning, and inspection results. Getting it right early keeps the work aligned and avoids costly adjustments later. Misjudging even a few inches can lead to overdesign, underperformance, or missed specs on inspections.

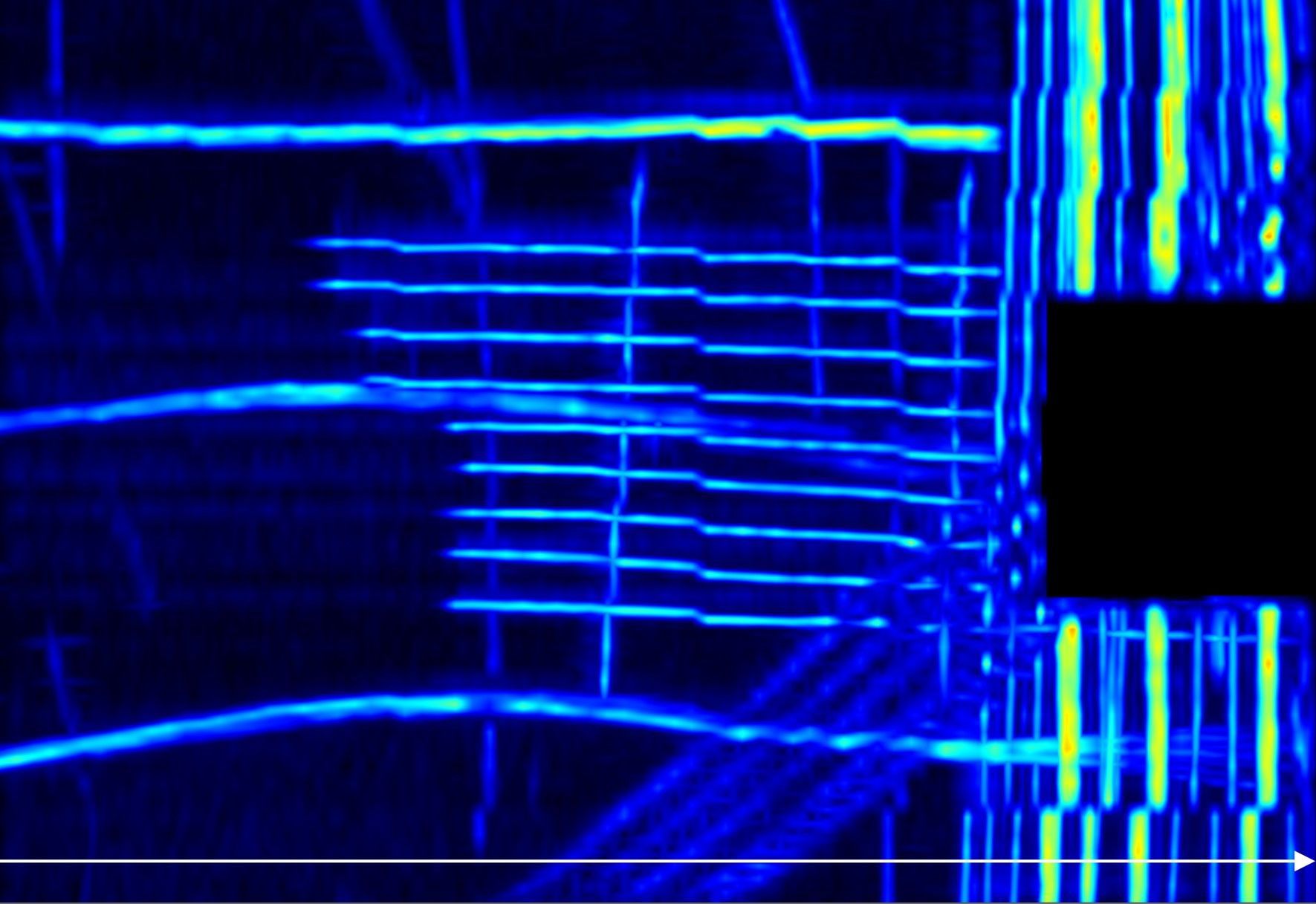

GPR construction tools simplify the process of measuring concrete thickness without destructive testing or drilling. Scanners provide a cross-sectional view, showing not only thickness but also variations across the surface. This proves useful on older structures, overlays, or slabs with unknown build history.

From structural engineers to field crews, having that data on hand helps teams make smarter calls about reinforcement, anchoring depth, and planning. It’s a clear, non-invasive way to confirm what's there before moving forward, and it’s become a routine step on jobs that depend on precision.

Detect Voids, Honeycombing, and Delamination

Surface cracks don’t always tell the full story. Issues like voids, honeycombing, and delamination can form inside concrete where they’re invisible until failure starts. GPR shows these problems early, before they affect structural performance or safety.

The scanner detects changes in material density, flagging weak spots that might not show up in a visual check. This makes it possible to identify internal gaps beneath slabs, within walls, or around columns without breaking them open. It’s especially useful in quality control, post-pour checks, or evaluating rehab work.

When the goal is to verify integrity without damaging the structure, GPR delivers fast, trustworthy insight. Crews can scan, review, and act on findings quickly, avoiding future repairs and reducing uncertainty on critical structures.

Scan Bridge Decks and Elevated Structures

Bridge decks and elevated concrete structures face heavy wear from traffic, weather, and time. Over the years, water infiltration and corrosion can break down internal layers long before signs appear on the surface. GPR gives inspection teams a fast, non-invasive way to scan for subsurface deterioration like delamination, corrosion zones, and voids. It produces high-resolution maps of reinforcing steel and deck condition without shutting down lanes or damaging the structure.

These scans make routine assessments more efficient and accurate, helping prioritize repairs and catch issues before they spread. Engineers can track changes over time and compare data from earlier scans to guide decisions. GPR supports routine monitoring across post-tensioned systems, elevated walkways, and older infrastructure, helping teams track safety conditions while keeping work uninterrupted.

Subsurface Mapping Before Building

Before excavation begins, knowing what lies underground shapes how a project unfolds. Old foundations, buried tanks, unmarked utilities, and soil inconsistencies all pose risks that slow work and raise costs. GPR construction scanning highlights these features early, giving project teams the insight needed to plan around hazards and avoid delays.

Unlike traditional locating methods that depend on access points or outdated records, GPR works across open ground and paved surfaces alike. It’s a non-destructive way to map what’s below without digging a single hole.

On large construction sites, this means faster surveys, fewer stoppages, and safer starts. From early planning to final prep,

subsurface mapping with GPR improves outcomes across every phase. It also helps define

ground penetrating radar depth based on the site's conditions and material composition.

Meet Safety Standards on Public Works Projects

Transit systems, schools, roadways, and government facilities all demand higher standards for documentation, risk management, and non-destructive testing. Public works jobs come with stricter safety rules and more scrutiny. Crews are expected to meet these requirements while keeping the project on schedule. GPR contributes directly to those efforts. It supports pre-construction surveys, structural assessments, and concrete scanning in live environments where shutdowns aren’t feasible.

Agencies and inspectors rely on accurate data to confirm work is being done safely, especially near utilities, post-tension cables, or structural elements. Because GPR doesn’t involve coring or excavation to get results, it’s a faster way to stay compliant. It also helps track conditions, making it easier to meet project specs and avoid rework.