What Is Ground Penetrating Radar (GPR)?

Ground Penetrating Radar (GPR) is a non-destructive tool used to map what’s beneath concrete, asphalt, or soil. It works by sending high-frequency radar signals into the ground. When those signals encounter a change in material, like a buried object or a void, they bounce back to the surface. The system records those reflections and builds an image of what’s below.

How Ground Penetrating Radar (GPR) Works

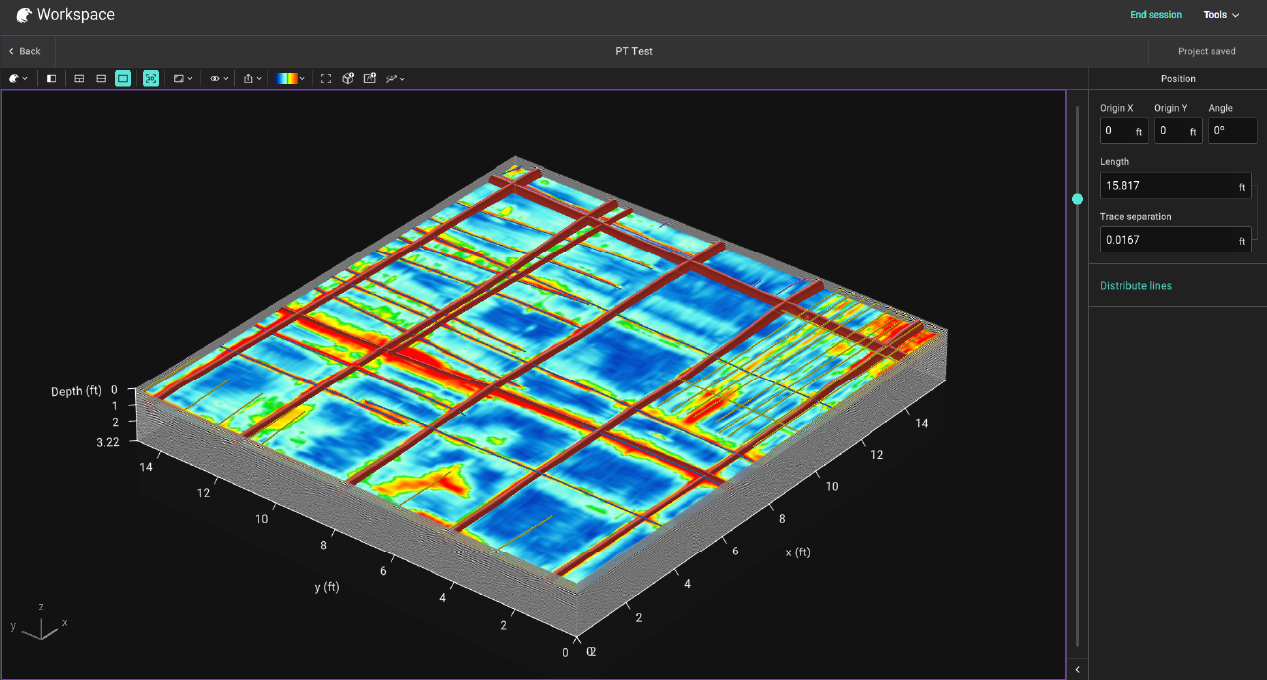

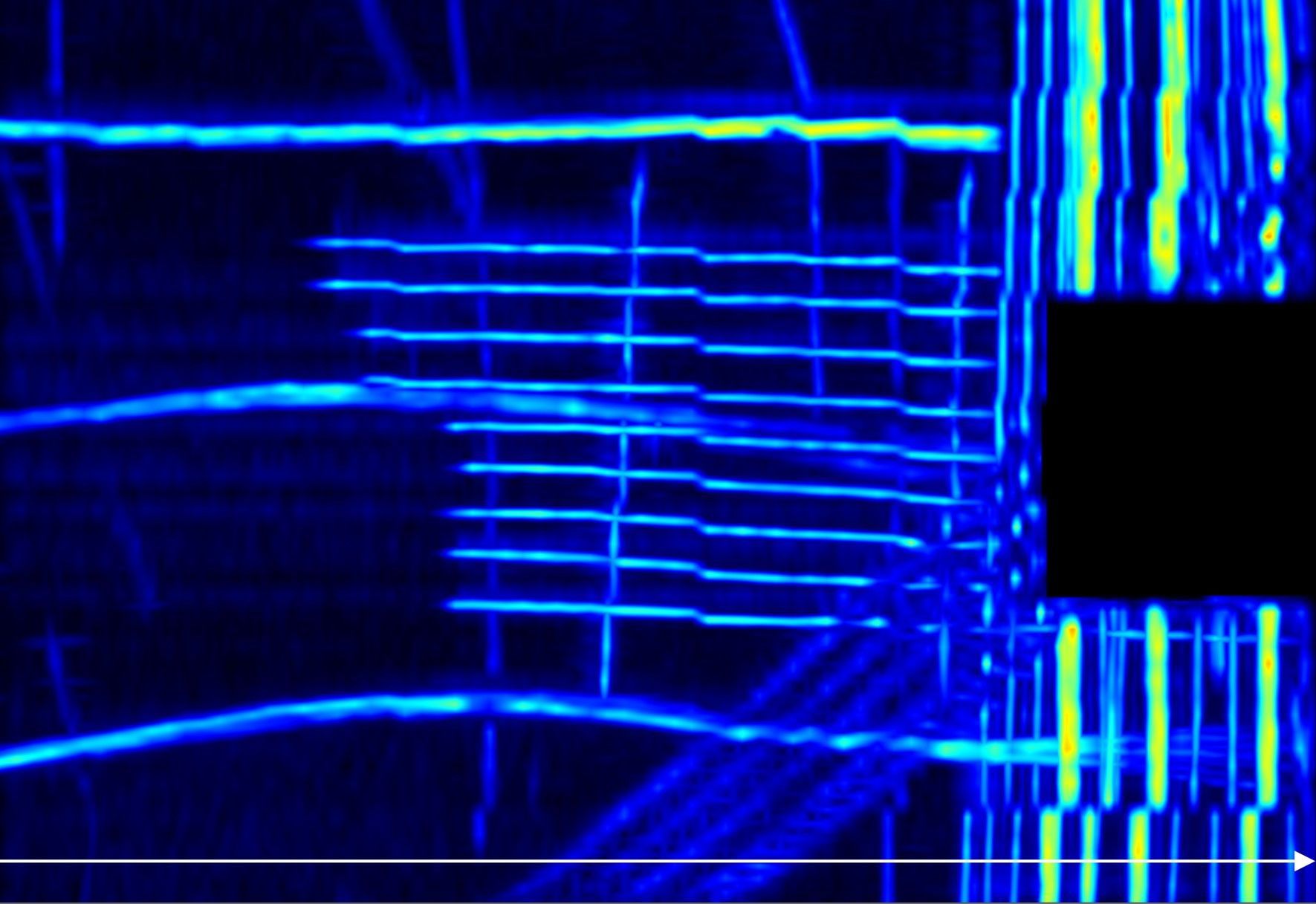

Ground penetrating radar (GPR) is a non-destructive imaging method that uses high-frequency radio waves to detect and map what’s beneath the surface. A transmitter sends electromagnetic pulses into the material, like concrete, asphalt, and soil, and a receiver collects the reflected signals. Different materials, like rebar, conduits, or PVC, respond differently. The result is a live image of what lies below, often displayed as cross-sectional slices or depth profiles, without the need for cutting, coring, or digging first.

This method is widely used because it's fast, accurate, and doesn’t damage the material being scanned.

Common Applications Across Industries

GPR plays a critical role across several trades, including construction, civil engineering, and geophysical work. Common applications include:

- Concrete scanning: Identify rebar, post-tension cables, conduits, and voids before any coring or cutting.

- Utility locating: Map underground infrastructure like electrical, water, or gas lines.

- Geotechnical work: Profile soil layers or locate sinkholes and voids.

- Structural inspection: Measure slab thickness or detect delamination and defects in concrete.

If you're working on anything that requires knowing what’s beneath the surface, GPR is the go-to.

Advantages of Using (and owning) GPR Equipment

When you own your own GPR scanner, you’re in control. Instead of waiting on third-party scanning services, you can scan when and where you need, keeping jobs on schedule and under budget. You’ll also build internal expertise, improve field safety, and reduce reliance on outside help.

Other key benefits:

- Avoid hits that damage utilities or equipment

- Verify safe zones before cutting or drilling

- Make faster, more informed decisions in the field

- Capture data for documentation and quality assurance

With proper training, software, and equipment, in-house teams can handle most scanning needs directly, giving you better control over safety and data quality.

Looking to Invest in GPR Technology?

At GPR USA, we help professionals choose the right GPR equipment for the work they do, with jobsite-ready scanning systems built for concrete and geophysical work. We offer hands-on GPR training, responsive support, and certified repairs to keep your gear working in the field.

As an authorized distributor for Screening Eagle / Proceq, we match contractors and engineers with tools that fit their specific needs. And if your scanner ever needs attention? Our concrete scanner repair services keep your equipment field-ready.

Don’t leave scanning to chance, or wait around for someone else to show up. Take control of your projects, improve safety, and do the job right the first time.

Contact us for more information and see how GPR USA can help you scan smarter.